Presenting OurProduct

Toyo Denki Eco-Drive Motort

EDM is a motor which used Interior Permanent Magnet (IPM) Synchronous Motor technology where by the magnet is located inside the rotor. This IPM motor will be able to get the benefit of increasing torque effects..

ED MOTOR for better future

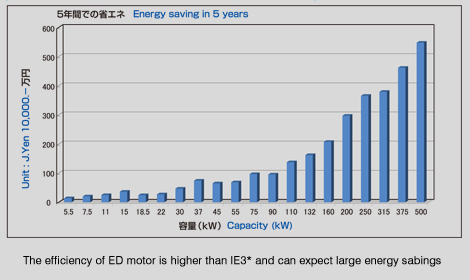

Deliver Energy Savings

Using our ED motors dramatically reduces CO2 emissions and saves energy. They deliver about 3% more efficiency than the NEMA standard for high-efficiency motors and 5% more for induction motors for our UF series inverters, thereby helping to lower our customer’s costs.

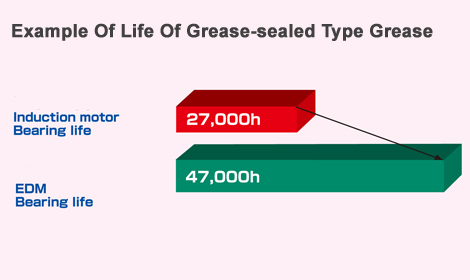

Long Bearing Life Decreases Maintenance Costs

Rotor loss is extremely low, which keeps bearing temperature low and extends their life by about a factor of two over induction motors. And since bearings do not have to be replaced very often, maintenance costs can be kept down.

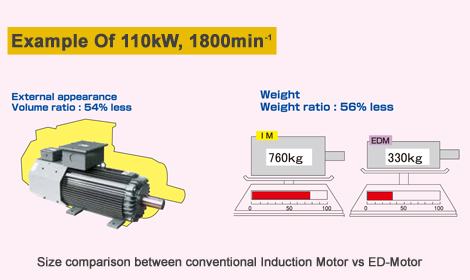

Small Size And Light Weight Enable Wide-Ranging Applications

Both weight and size have been reduced by 50% compared to a conventional induction motor (110 kW 1,800 min-1 model). The use of an ED motor gives you freedom of design for a wide range of machinery.

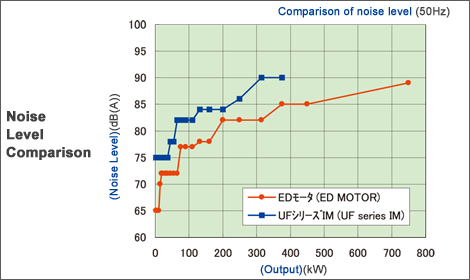

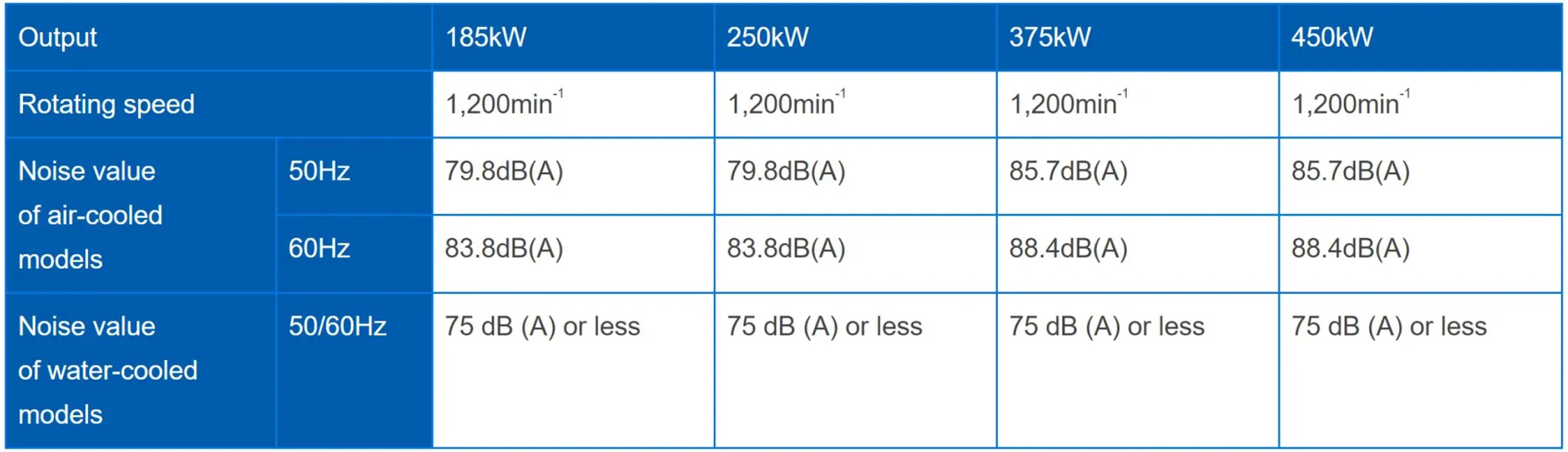

Further Noise Reduction Through Water Cooling

Water cooling (optional) dramatically cuts noise, just one more way this motor is environmentally friendly. The water jacket section is plated, allowing the use of factory coolants as is.

Choice Of Product

.